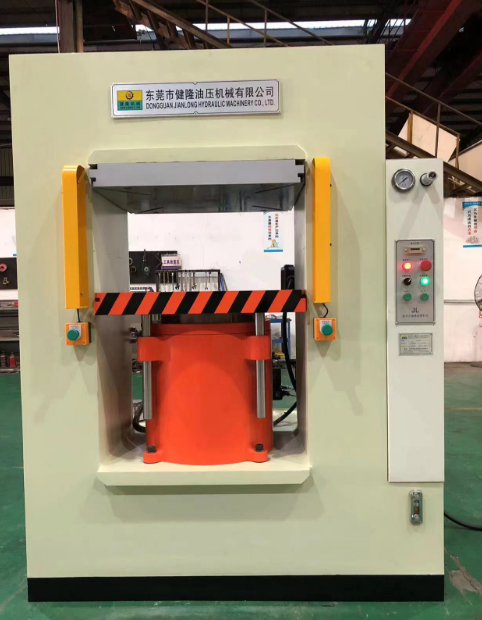

The quality of the frame press produced by the manufacturer is very good. As long as it is in normal operation, there is no particularly serious problem. However, there will inevitably be some minor problems during use. In this case, troubleshoot the fault in time. Find a dedicated person to deal with the problem. If there is a problem with the hydraulic press, it is likely that it will not be used for a long time, and there may even be hidden dangers. If the frame hydraulic press does fail, how should we deal with it?

First, troubleshoot. When buying a frame hydraulic press, the other party should tell us some simple treatment methods, especially if the equipment cannot continue to run or the motor problem must be solved in time. It is recommended to check whether the motor can run normally and whether the indicator light can blink normally between each use. If there is a problem, you can consider whether there is an internal problem and pay attention to the investigation. Troubleshooting is really difficult, so it is more convenient to go directly to the after-sales service person and have the other party carry out an internal inspection.

Two, timely replacement of parts. There will inevitably be some small problems during the use of the frame hydraulic press, especially when the wear is serious, which may directly affect the operation of the equipment, so it is also important to replace the internal parts regularly. Long-term cooperation with the manufacturer's after-sales maintenance network is recommended. Usually, if something goes wrong in time, someone will take care of it, but the cost of replacing the part may require us to pay for it. Contact the other party and consult the price, so as to facilitate maintenance.

In many industries, the daily use of frame oil presses is high. Although such equipment can be operated frequently, if poorly maintained, it is prone to failure and internal parts are prone to wear. Most buyers buy more hydraulic presses at a time, their daily use is more frequent, and they may pay less attention to maintenance later. In fact, the maintenance of the hydraulic press is not very difficult. As long as you can grasp the maintenance points, ensuring results is still very simple.

Point one, pay attention to daily cleaning. Many frame oil press failures are caused by some stains. Such stains may have arisen during the production process, or some other surrounding material may have entered the hydraulic press. Some dust in the air will also affect the hydraulic press, so clean the hydraulic press after each use. Handled by a special person. Simple daily cleaning does not waste too much time, so later maintenance will become simpler, the wear and tear of the equipment will be greatly reduced, and more costs can be saved.

Two o 'clock, check before use. Although many manufacturers are said to do a good job of protecting frame oil presses on a daily basis, if they can be carefully checked before use, the chance of equipment wear will be reduced. In addition, hydraulic presses usually have problems with motors. If it is not checked before use, there may also be a production risk. So the recommended benefit is to be able to do a complete check beforehand to make sure there are no problems with the device before continuing to use it. If the equipment fails, timely maintenance is actually a good maintenance.

Contact: Miss.Li

Phone: 18822971180

Tel: 86-18822971180

Email: lifuyan78@gmail.com

Add: Guangyi Industrial Park, No. 2, Tanglip Jinfu West Road, Liaobu Town, Dongguan City, China

We chat