Hydraulic press through the liquid pressure to make the workpiece under static pressure deformation or pressed forming. In this process, the working medium plays a crucial role. There are two main working media of hydraulic press: emulsion and oil. A hydraulic press that uses emulsion as the working medium is usually called a hydraulic press, while one that uses oil as the medium is called an oil press. Although the working medium is different, they are collectively called hydraulic presses.

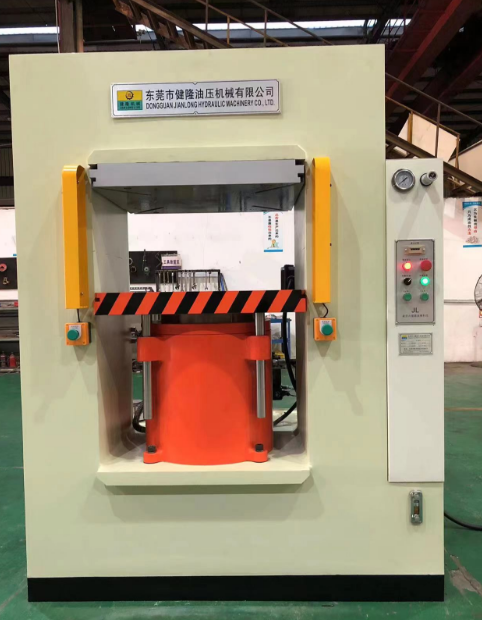

The structure of hydraulic press mainly includes two parts: body and hydraulic system. The body is the skeleton of the hydraulic press, which bears all the working pressure and load. The hydraulic system is responsible for providing and controlling the pressure and flow required by the hydraulic press. The close combination of these two parts makes the hydraulic press able to efficiently and stably complete various work tasks.

The working cycle of the hydraulic press includes the steps of no-pass down, working stroke, holding pressure, return stop, ejector cylinder ejector, ejector cylinder return, etc. The precise execution of these steps depends on the precise control of the various valves in the hydraulic system. The opening and closing of each valve is directly related to the efficiency and accuracy of the hydraulic press. Therefore, in the design and manufacturing process of hydraulic press, the selection and commissioning of valves are particularly important.

There are various types of hydraulic presses, which can generally be divided into single column, double column, four column and gantry hydraulic presses. These different types of hydraulic presses have their own characteristics and application scenarios. For example, the single-column hydraulic press is compact and suitable for working environments with limited space; The four-column hydraulic press is favored by many industries for its stability and high precision.

With the continuous progress of science and technology, hydraulic press is also constantly developing and innovating. The application of cutting-edge technologies such as the Internet of Things and artificial intelligence has made the hydraulic press develop in the direction of digitalization, intelligence, integration and green. The application of these technologies not only improves the working efficiency and accuracy of the hydraulic press, but also greatly reduces energy consumption and environmental pollution.

Digital technology allows the parameters of the hydraulic press to be monitored and adjusted in real time, thus ensuring that the equipment is always in the best working condition. The application of intelligent technology makes the hydraulic press can automatically identify and adapt to different working environments and task requirements, which greatly improves the flexibility and adaptability of the equipment.

Integration technology integrates multiple functional modules in a compact system, which not only reduces the footprint of the equipment, but also simplifies the operation process. This highly integrated hydraulic press is particularly suitable for automated production lines and intelligent manufacturing scenarios.

Green technology is one of the important trends in the development of hydraulic presses. By adopting environmentally friendly materials, optimizing energy utilization and improving waste recovery, the environmental impact of hydraulic presses can be significantly reduced. This not only conforms to the current global trend of environmental protection, but also reduces operating costs for enterprises and improves market competitiveness.

The advantages of hydraulic press are self-evident. It works smoothly, with low vibration and noise, making the working environment more comfortable and safe. The characteristics of simple structure, convenient operation and easy manufacture make the hydraulic press widely used in various fields. Whether in automotive manufacturing, aerospace, petrochemical or other industries, hydraulic presses play a pivotal role.

Contact: Miss.Li

Phone: 18822971180

Tel: 86-18822971180

Email: lifuyan78@gmail.com

Add: Guangyi Industrial Park, No. 2, Tanglip Jinfu West Road, Liaobu Town, Dongguan City, China

We chat