The role, performance requirements and installation mode of the cooler in the hydraulic press In general, the cooler should be assembled in the hydraulic system of the hydraulic press. Because the cooler plays a vital role in the hydraulic press:

1. There should be enough heat dissipation area to keep the oil temperature within the allowable range.

2. The pressure loss should be small when the oil passes.

3. When the system load changes, it is easy to control the oil to maintain a constant temperature.

4. Have enough intensity.

Cooler installation method: The cooler is generally installed in the return pipeline or low pressure pipeline, if necessary, it can also be installed in the oil outlet of the hydraulic pump to form an independent cooling circuit.

The details are as follows: 1. The cooler is installed at the overflow port of the main relief valve. The characteristics of this installation method are: the hot oil generated by the relief valve is cooled directly, and it is not affected by the impact pressure of the system, the check valve plays a protective role, and the stop valve can make the hydraulic oil directly back to the tank when starting.

2. The cooler is installed on the main oil return circuit. The characteristics of this installation method are; The cooler is installed directly on the main return oil circuit, and the cooling speed is fast, but when the system circuit has impact pressure, the cooler is required to withstand higher pressure. 3. Independent cooling circuit The advantages of independent cooling circuit are; A separate hydraulic pump passes the hot working medium into the cooler, which is not affected by hydraulic shock.

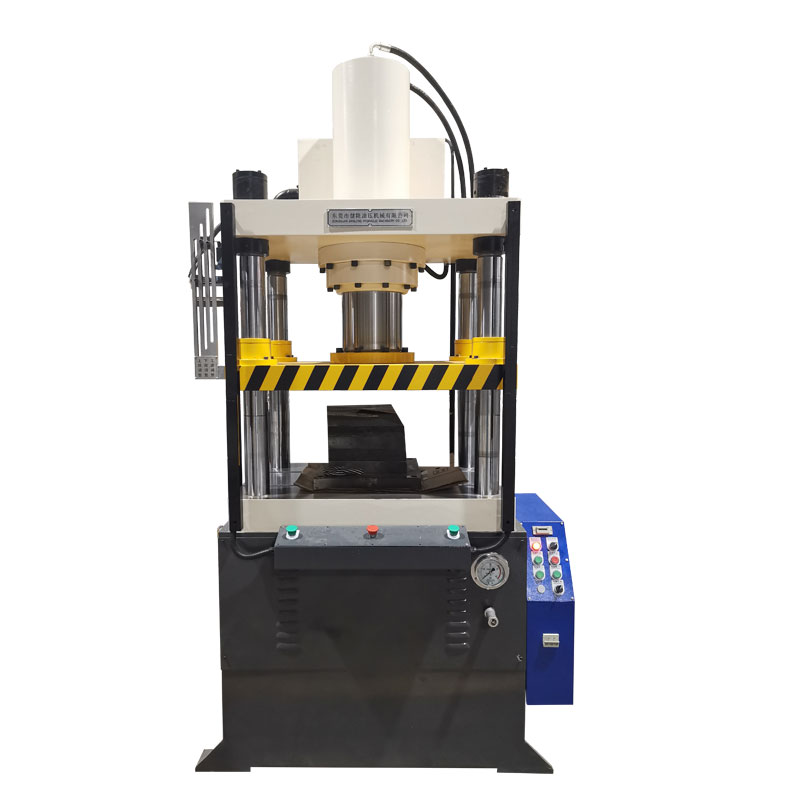

Four column single action hydraulic press

Contact: Miss.Li

Phone: 18822971180

Tel: 86-18822971180

Email: lifuyan78@gmail.com

Add: Guangyi Industrial Park, No. 2, Tanglip Jinfu West Road, Liaobu Town, Dongguan City, China

We chat