I. Summary

Hydraulic press is a commonly used hydraulic machine, which is widely used in metal processing, plastic processing, pressing and forming industries. It has the advantages of simple structure, stable and reliable, convenient operation, etc., and is one of the indispensable equipment in the processing and production process.

Second, check the equipment

Before using the hydraulic press, it is necessary to check whether the equipment is working properly to ensure the safety and accuracy of the operation. The specific steps are as follows:

1. Check whether the power supply and cable are correctly connected, and ensure that the power switch is off;

2. Check whether the various parts of the hydraulic press are intact, loose or deformed;

3. Check whether the heater and temperature controller are normal;

4. Check whether the throttle, pressure gauge, speedometer and other devices are in normal condition.

3. Start the device

After checking the device, start the device as follows:

1. Turn on the power switch of the device.

2. Set operating parameters, including heating temperature, heating time, pressure, speed, etc.

3. Start the hydraulic station and increase the pressure of the hydraulic station;

4. Open the hydraulic valve and lift the workbench of the hydraulic press.

4. Adjust the operating parameters

The hydraulic press requires a series of parameter adjustments to ensure the normal operation of the equipment and the accuracy of processing. The specific steps are as follows:

1. Adjust the heating temperature and heating time to make the hot plate reach the set temperature;

2. Adjust the lifting height, processing time and speed to ensure that the equipment works as required;

3. Adjust the pressure to ensure that the working pressure of the equipment meets the processing requirements.

Five, start the hydraulic press

After adjusting the operating parameters, the hydraulic press needs to be started for processing. The specific steps are as follows:

1. Place the workpiece and adjust the position of the workpiece to ensure that the position is accurate;

2. Press the start button, the hydraulic press starts to work;

3. Observe the workpiece processing, adjust the parameters to ensure the accuracy and quality of processing.

6. End the operation

After the processing is completed, it is necessary to end the operation, the specific steps are as follows:

1. Turn off the power switch of the device.

2. Close the hydraulic valve to release the pressure;

3. Close the hydraulic station and let the equipment cool down;

4. Clean the equipment, including removing oil, dust, and debris.

This paper introduces the basic operation flow of hydraulic press, including checking equipment, starting equipment, adjusting operation parameters, starting hydraulic press and so on. By correctly operating the hydraulic press, safety and processing quality can be ensured and production efficiency can be improved.

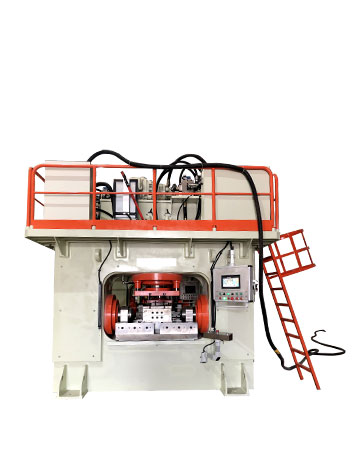

Multidirectional forging four-column hydraulic press

Contact: Miss.Li

Phone: 18822971180

Tel: 86-18822971180

Email: lifuyan78@gmail.com

Add: Guangyi Industrial Park, No. 2, Tanglip Jinfu West Road, Liaobu Town, Dongguan City, China

We chat